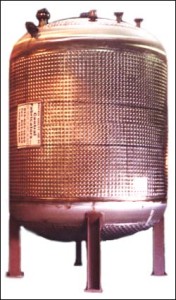

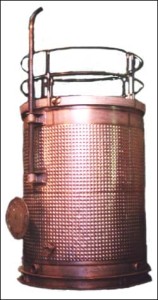

Our standard stainless-steel dimple jacket will handle 200 PSI at 400°F. To meet your needs, we can custom fabricate heating and cooling jackets for reactors that require high pressure and temperature.

The majority of jackets are constructed of stainless steel. However, custom jackets are available in:

- Inconel

- Carbon Steel

- Hastelloy

- Monel

- Incoloy, and others

We can provide:

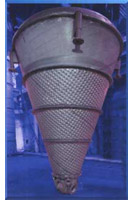

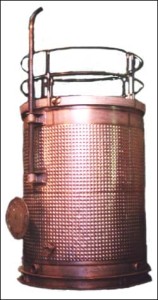

- Complete dimple jacketed vessels

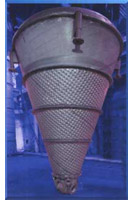

- Dimple jacketed components

- Sheets of dimple material

- Removable panel coils

Stainless-steel dimple jackets can be made for any size vessel.

As a trusted dimple jacketed supplier, we make sure all of our jackets and dimple jacketed vessels are in compliance with the ASME code. We have years of experience as a jacketed reactor and jacketed tank manufacturer. Contact us today to learn more about our selection of dimple jacketed tanks and reactors.